Schaap’s ‘Back Nine’ Dairy Provides Milk for Garden Fresh Feta Cheese

In August’s Picnic menu, we are featuring the “Classic Greek Salad” offered at dinner only. One of the key ingredients that makes the Greek salad so delicious is the feta cheese. Feta is a rich and creamy soft cheese of Greece. In order to make great feta, it starts with the milk. One example of a farm that supplies their milk to manufacture cheese is “Back Nine” dairy farm.

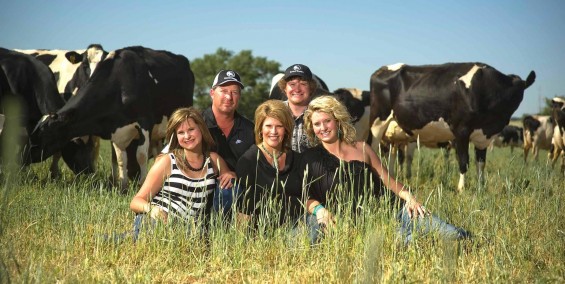

Third generation dairy farmer Art Schaap and his family totally understand the Garden Fresh “Discover Fresh” positioning of “each day begins fresh and fresh begins here.” Their dairy business is a 24/7 operation and each day begins fresh, typically long before the sun comes up.

The Schaap family dairy history began with Art’s grandfather, Ids, who moved to Artesia, CA, from his native Holland shortly after the end of World War II. Art’s father, Andy, moved the family to New Mexico in the late 1970s as most of the dairy farms in the Los Angeles area were being gobbled up for housing development.

Art and his entire family, wife, Renee, son, Ryan, and daughters, Jennifer and Amanda, are involved in the dairy business one way or the other. Amanda works for an organic dairy cooperative in LaCrosse, WI, but the rest of the family work on one of their three dairies (one organic and two conventional) in the Clovis, NM, area. Their “Back Nine” dairy provides the bulk of milk used to produce the Ithaki feta cheese now available at Garden Fresh restaurants.

Tucumcari Mountain Cheese Factory, Inc. based in Tucumcari, NM obtains the vast majority of its milk from Art’s dairy farms. Art acquired a significant ownership position in Tucumcari Cheese in 2012. Chuck Krause is the founder of Tucumcari Cheese and a fourth generation Wisconsin cheese maker.

Feta is a specialty cheese, explains Ed Zimmerman, Coastal Marketing Managing Partner of Tucumcari Cheese. In the United States, about 100 million pounds are produced annually and that is up about 25% from five years ago,” Ed says. Driving growth in the category is the versatility of recipes where feta is used in meals throughout the day such as omelets, salads, appetizers, and entrée dishes. “The highest quality feta cheese starts with fresh milk that has just the right amount of butterfat and protein,” Art says.

“Tucumcari Cheese has focused on making feta cheese for the past 20 years and we’ve learned that the best breeds for providing high quality milk yielding high quality butterfat and protein are Brown Swiss, Jerseys, and Holsteins, and those breeds make up our 1,400 head herd at the Back Nine Dairy,” he said. To maximize the highest potential volume and butterfat content, each cow is monitored by what Art calls a “computer-run feed program” that ensures the feed rations are adjusted to “hone in on what cows are eating to a science.” Each cow also has a radio frequency identification tag so Art and his team know the cow’s life history, including date of birth, how much milk she is producing, how many days she has been producing and if she is pregnant. Most cows produce milk about 300 days a year, following the birth of a calf. A cow is what is called “dry” for about 60 days a year.

Once the milk is off loaded from the tankers it quickly moves into the “make room” where cheese cultures, rennet, and an enzyme, lipase, which gives feta cheese its unique flavor, is used in the make process. Once separation of curds from the whey is complete, the cheese is pressed overnight. Then it is in brine for 12-14 hours before it goes to either be crumbled or packaged into pails. The cheese is then cooled to 35-38 degrees and ready to ship.

Cows at the Back Nine are milked three times a day, starting early in the morning and about eight hours apart. About 50,000 pounds of milk from the Back Nine dairy is shipped daily via semi-truck tankers to Tucumcari Cheese, about 70 miles from the farm. Fresh milk from the cow is usually being made into feta cheese on the evening of milking or early the next day. Making feta is a two-day process.

“Our philosophy is we want our customers happy,” Art says. “Without happy customers we can’t do what we do. We love dairy farming and hope our kids continue to grow and evolve the business in smart and innovative ways.”

The Schaap family dairy history began with Art’s grandfather, Ids, who moved to Artesia, CA, from his native Holland shortly after the end of World War II. Art’s father, Andy, moved the family to New Mexico in the late 1970s as most of the dairy farms in the Los Angeles area were being gobbled up for housing development.